Waste Heat Recovery Systems

PENTA SOLUTIONS

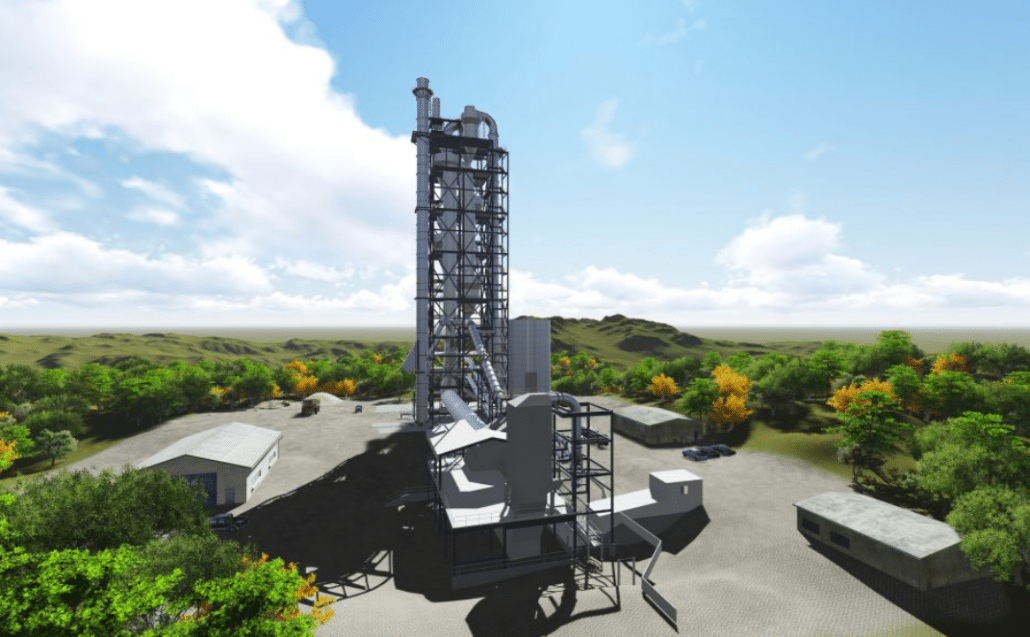

Waste Heat Recovery Systems Integration & Design

- We review plant operations and assess available waste heat by validation from process simulations.

- PENTA evaluates the cyclic pattern of moisture each month of the year to establish tangible metrics for how the moisture in raw materials and coal impact the available waste heat.

- Evaluation steps help us determine the optimum size and configuration of the WHR system that will optimally suit your facility.

- Conceptualizing and designing the most cost-effective layout for each project is a priority. PENTA’s top considerations also include designing WHR systems that easily integrate into existing facilities, and minimize plant interruptions/downtime.

- PENTA develops Bid Documents and specifications for the procurement of the WHR system. We evaluate the bids and make a studied recommendation based on many factors so the most beneficial system can be procured and installed.

- We estimate the CapEx, OpEx and develop an Economic Analysis to establish the viability of each WHR project.

- PENTA assists you with planning and then implementing a waste heat recovery system for each project in the most effective way possible.

BENEFITS:

- We believe employing “Green Energy” is the right way to conserve energy and lower your carbon footprint.

- Lowering your dependence on grid power from the utility company is one of the benefits of installing a WHR system.

- We also investigate ways to seamlessly integrate the WHR system with an existing power plant to minimize investment costs.

EXPLORE ADDITIONAL

PENTA SERVICES

READY TO OPTIMIZE YOUR CEMENT OPERATIONS?

RECENT PROJECTS

Cement Plant Expansion Structural Engineering

PENTA supported a $500+ Million cement plant modernization project in the Midwestern United States providing structural engineering services to an international equipment supplier.

EPCM Waste-To-Fuel Facility

PENTA was engaged to develop a waste-to-fuel production facility that produces a fuel source that can be used in calcination as a substitute for fossil fuels.

Tire Derived Fuel Facility

PENTA provided the engineering for the installation of a tire derived fuel (TDF) system at a plant in TX.

READY TO

OPTIMIZE

YOUR INDUSTRIAL

OPERATIONS?

Discover how PENTA’s tailored solutions can solve your toughest challenges. Reach out for expert guidance today.