[av_section min_height=’custom’ min_height_px=’150px’ padding=’large’ shadow=’no-shadow’ bottom_border=’no-border-styling’ bottom_border_diagonal_color=’#333333′ bottom_border_diagonal_direction=” bottom_border_style=” custom_arrow_bg=” id=” color=’main_color’ custom_bg=” src=’http://www.penta.net/wp-content/uploads/2016/07/rotary-kiln-plant-Chile-7.jpg’ attachment=’1040′ attachment_size=’full’ attach=’parallax’ position=’top left’ repeat=’stretch’ video=” video_ratio=’16:9′ overlay_enable=’aviaTBoverlay_enable’ overlay_opacity=’0.2′ overlay_color=’#000000′ overlay_pattern=” overlay_custom_pattern=” av_element_hidden_in_editor=’0′]

[av_heading heading=’NFPA 652′ tag=’h1′ style=’blockquote modern-quote modern-centered’ size=’50’ subheading_active=’subheading_below’ subheading_size=’20’ padding=’0′ color=’custom-color-heading’ custom_font=’#ffffff’ av-medium-font-size-title=” av-small-font-size-title=” av-mini-font-size-title=” av-medium-font-size=” av-small-font-size=” av-mini-font-size=” admin_preview_bg=”]

Dust Hazard Analysis (DHA) Study

Coal & Solid Fuels handling facilities

[/av_heading]

[av_hr class=’custom’ height=’50’ shadow=’no-shadow’ position=’center’ custom_border=’av-border-thin’ custom_width=’20%’ custom_border_color=’rgba(255,255,255,0.76)’ custom_margin_top=’30px’ custom_margin_bottom=’30px’ icon_select=’yes’ custom_icon_color=’#ffffff’ icon=’ue8bf’ font=’entypo-fontello’]

[/av_section]

[av_textblock size=” font_color=” color=” av-medium-font-size=” av-small-font-size=” av-mini-font-size=” admin_preview_bg=”]

The most recent NFPA publication applicable to cement and lime plants, NFPA 652, mandates that every industrial facility handling solid fuels needs to complete a Dust Hazard Analysis (DHA) Study by August 2018, after which deadline plants risk becoming non-compliant.

Most cement and lime plants use coal and other solid fuels for their operation and therefore come under the purview of this mandate.

NFPA 652 “Standard on the Fundamentals of Combustible Dust” was created to include several older standards (NFPA-61, 68, 654) as a single go-to source for a systematic study of fire and explosion hazards and to develop mitigation measures.

The DHA Study promotes awareness of the following principles:

- Fuel management controls

- Ignition source controls

- Restraining the spread of any combustion event

It applies to equipment handling coal and other combustible dusts, including Dust Collectors, Bucket Elevators, Drag and Screw Conveyors, Pneumatic Conveying Systems, and Storage Bins and Silos.

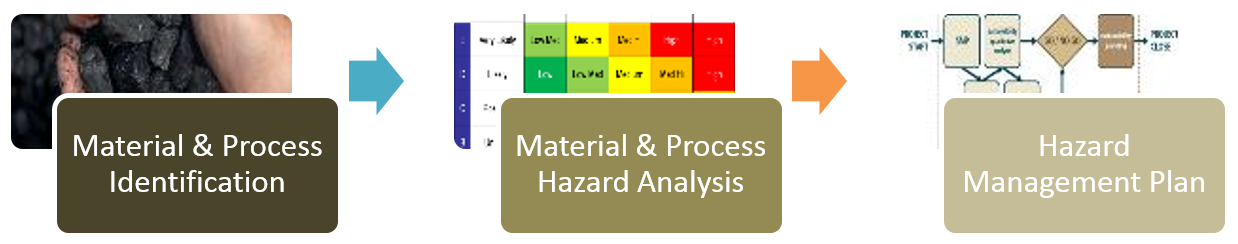

DHA consists of 3 main steps to complete the analysis.

Material and Process Identification:

- Determine the characteristics of the dust with tests recommended in NFPA 652 to assess how combustible or explosible the dust is.

- Identify the process areas where there exists potential combustibility and explosibility

Material and Process Hazard Analysis:

- Evaluation of every process area that could promote fire and explosion hazards

- For each identified hazard area, the following aspects are analyzed:

- Is the dust combustible in this segment?

- Is the dust suspended in air?

- Is the dust concentration such as to support a deflagration?

- Is there an ignition source that could ignite the dust cloud present?

- What hazard management controls are in place?

Hazard Management Plan

The Hazard Management Plan outlines the mitigation measures to be implemented for managing the suppression of deflagration and/or isolation of the source of deflagration. A written management system is developed for operating the facility to prevent or mitigate fires, deflagrations, and explosions from combustible particulates.

NFPA 652 outlines the topics to be covered in DHA and recommends a format to present the report.

PEC Consulting can help carry out a DHA Study for new or existing cement & lime plants and help the clients to develop a Hazard Management Plan.

[/av_textblock]

[av_hr class=’custom’ height=’50’ shadow=’shadow’ position=’center’ custom_border=’av-border-fat’ custom_width=’100%’ custom_border_color=” custom_margin_top=’30px’ custom_margin_bottom=’30px’ icon_select=’yes’ custom_icon_color=” icon=’ue81e’ font=’entypo-fontello’ admin_preview_bg=”]

[av_four_fifth first min_height=’av-equal-height-column’ vertical_alignment=’av-align-middle’ space=” margin=’0px’ margin_sync=’true’ padding=’0px’ padding_sync=’true’ border=” border_color=” radius=’0px’ radius_sync=’true’ background_color=” src=” attachment=” attachment_size=” background_position=’top left’ background_repeat=’no-repeat’ animation=” mobile_breaking=” mobile_display=”]

[av_textblock size=” font_color=” color=” av-medium-font-size=” av-small-font-size=” av-mini-font-size=” admin_preview_bg=”]

This article was contributed by Mohammed Dimah, Process Engineer for PEC Consulting, Mr. Dimah has a BS in Chemical Engineering from the University of Technology, Baghdad, Iraq, and a Master’s in Chemical Engineering from the Polytechnic University of Valencia, Valencia, Spain. He can be reached at info@peccg.com

Copyright © PENTA Engineering Corp. 10123 Corporate Square Dr, St Louis, MO 63132

[/av_textblock]

[/av_four_fifth]

[av_one_fifth min_height=” vertical_alignment=” space=” custom_margin=” margin=’0px’ padding=’0px’ border=” border_color=” radius=’0px’ background_color=” src=” background_position=’top left’ background_repeat=’no-repeat’ animation=” mobile_breaking=” mobile_display=”]

[av_image src=’http://www.penta.net/wp-content/uploads/2018/02/M.-Dimah-180×180.jpg’ attachment=’3927′ attachment_size=’square’ align=’center’ styling=” hover=” link=” target=” caption=” font_size=” appearance=” overlay_opacity=’0.4′ overlay_color=’#000000′ overlay_text_color=’#ffffff’ animation=’no-animation’ admin_preview_bg=”][/av_image]

[/av_one_fifth]