LIME

PENTA MARKETS

Lime

PENTA has extensive experience in the design, operations, and construction of chemical grade lime plant systems, with special emphasis on calcining and hydrating. Our in-depth knowledge of the lime industry and comprehensive services allows us to completely develop projects from conceptual design to start-up. Our services include:

Feasibility Studies: Capital and operating cost estimates, process evaluations, and operations analysis.

Engineering Design of Cement Plant Systems: The core business of PENTA is in the engineering of heavy industrial facilities. Our highly experienced multi-disciplinary team covers:

Quarrying and Raw Materials Preparation: Geological exploration and study of the limestone quarry to determine the quality of the rock and its suitability for the production of lime; quarry development and mining plans; crushing, and screening.

Grinding and Milling: Design of optimum systems for drying and grinding in ball and roller mills, roller presses, classification by high-efficiency separators, cyclones, and screens.

Stockpiling and Reclaiming Systems: Storage piles, stackers, traveling tripper conveyors, apron and reclaim feeders.

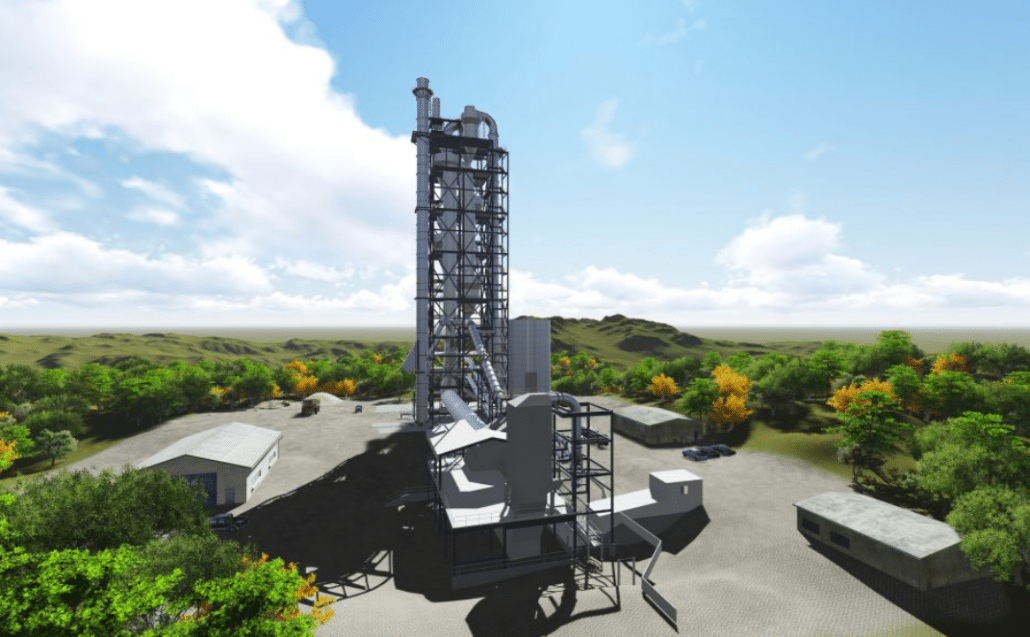

Pyroprocessing: Kiln feed systems; vertical and rotary preheater kilns; kiln firing systems including coke, coal, and natural gas firing systems; pollution control systems consisting of air / air heat exchangers; fabric dust collectors, electrostatic precipitators and fans.

Hydration: Ambient and pressurized hydrator systems; product grinding and classification systems including high surface hydrators, mills, air separators, and other processing and materials handling equipment.

Materials Handling: Bulk materials handling such as belt, screw and air gravity conveyors, bucket, pan conveyors and bucket elevators.

EFFICIENT SOLUTIONS FOR

GLOBAL LIME PROJECTS

3D technology is just one way we build industrial plants right the first time so all parties experience minimal risk and desired project outcomes.

PENTA has extensive experience with air pollution control systems and works closely with the Portland Cement Association (PCA) and other relevant industry associations.

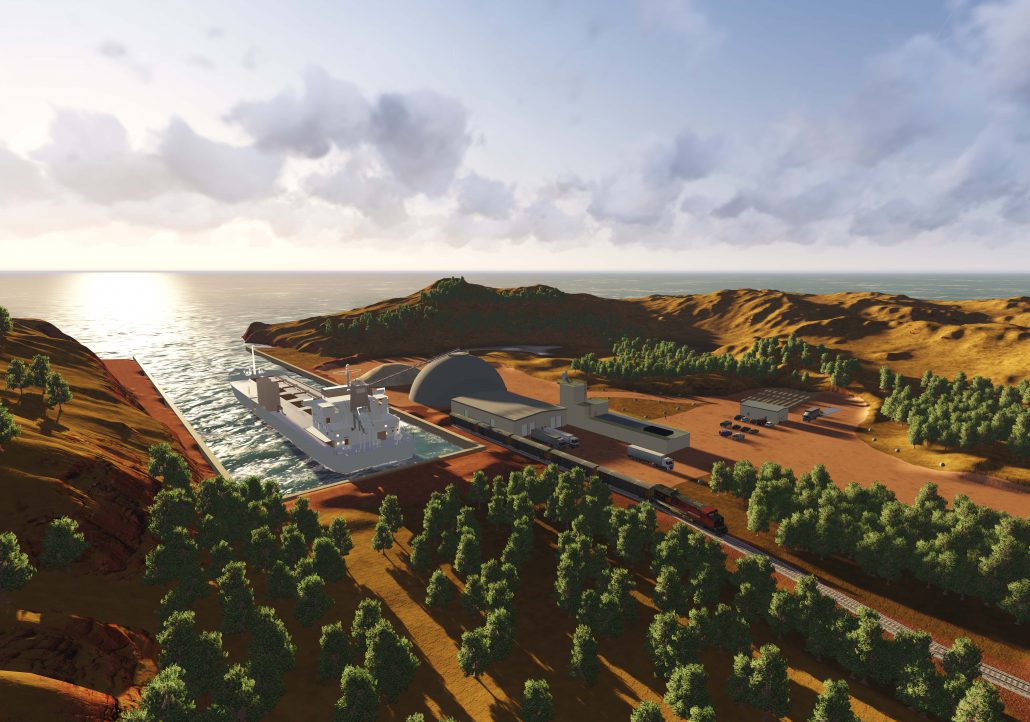

PENTA collaboratively works with clients to provide design/build bulk transfer terminal solutions that grow their businesses.

Storage: Storage facilities such as concrete silos, steel tanks, and dome structures; bagging systems and warehousing.

Loading and Unloading Facilities: Truck, rail, or marine facilities for loading and unloading raw materials and finished products.

Instrumentation and Process Control: design of instrumentation scheme and process control loops.

Commissioning and Start-up: PENTA’s comprehensive commissioning plan lays out the specifics on how the project will be put into operation. In addition, PENTA assists its clients so that they can accurately plan a ramp up for production to full capacity when the project is completed.

Plant & Company Valuations: comprehensive valuations that take into consideration business assets, historical earnings, market, mining reserves, production methods, reliability, plant personnel, management, financials and future projections.

READY TO OPTIMIZE YOUR CEMENT OPERATIONS?

EXPLORE ADDITIONAL

PENTA SERVICES

RECENT PROJECTS

Lime Brownfield EPCM Project

A lime industry client wanted to establish a new processing plant at an existing operation to produce a new product to meet market demand.

EPCM 1050 STPD Lime Kiln Construction

PENTA has been completing lime kiln upgrade projects on an EPCM basis working closely together with all project stakeholders for a successful project completion.

EPCM 1200 STPD Lime Kiln Construction

PENTA has been completing lime kiln construction projects on an EPCM basis working closely with our clients’ project teams.

READY TO

OPTIMIZE

YOUR INDUSTRIAL

OPERATIONS?

Discover how PENTA’s tailored solutions can solve your toughest challenges. Reach out for expert guidance today.