Overview

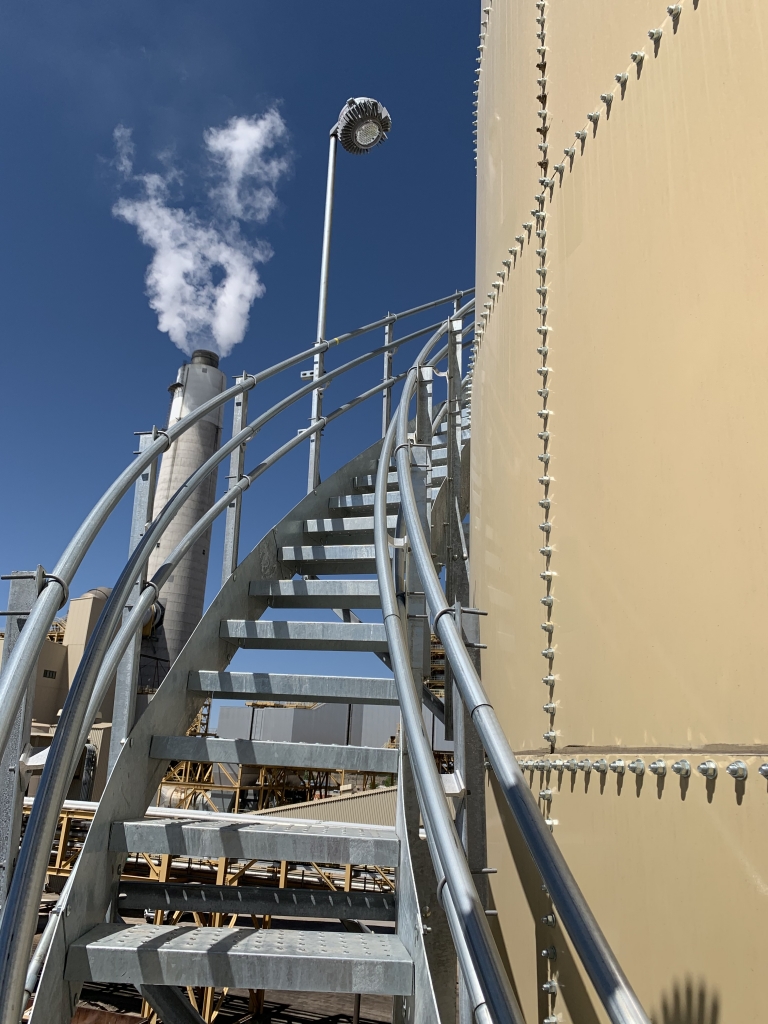

PENTA provided basic and detail engineering for the installation of a fly ash handling system at an existing power plant to dispatch over one million short tons of dry fly ash per year by rail and truck. PENTA developed the design accounting for plant operating and logistics requirements. Since the project was at an existing plant operation, 3D scanning was performed along with survey and geotechnical investigation. Engineering included civil, structural, mechanical and electrical design, equipment evaluation and recommendation, construction bid package development and evaluation with Client approval. PENTA also developed project schedule and EPC project budget. The fly ash handling system consisted of pneumatic conveying and mechanical conveying via bucket elevator transporting the fly ash from the existing fly ash silos to a new silo capable of loading both railcars and trucks simultaneously.