Overview

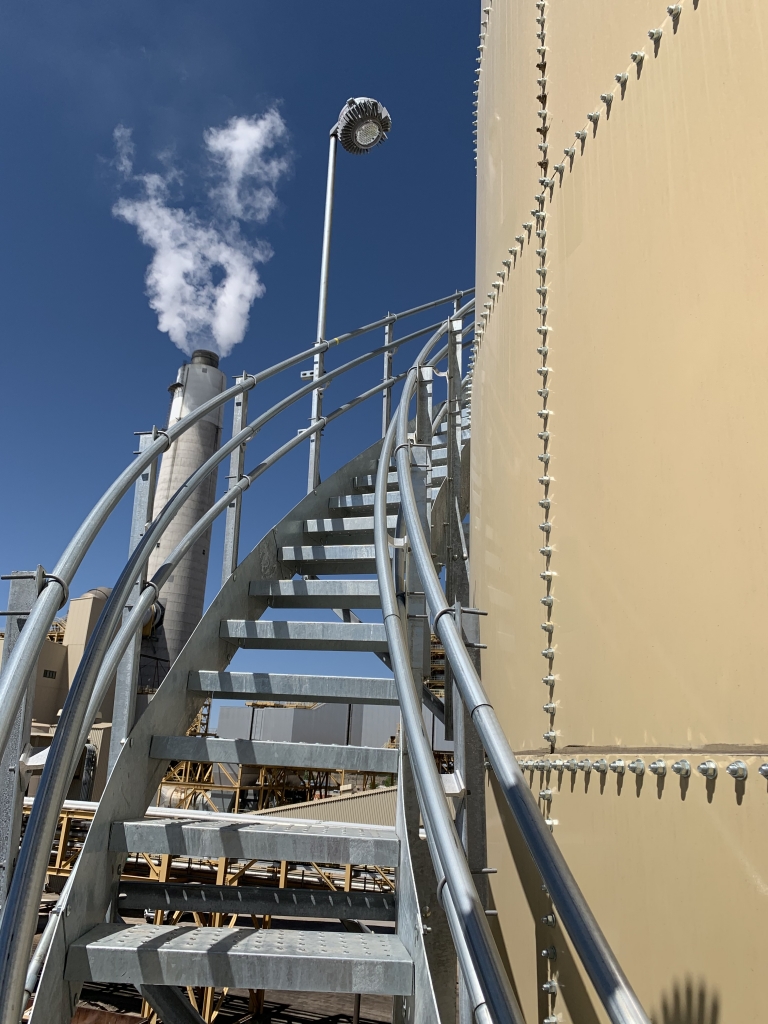

Hagerstown Cement Plant Expansion

Conversion of existing long dry kiln to a preheater/precalciner kiln and increasing the plant capacity from 1500 Mtpd to 2400 Mtpd clinker, which was part of a larger modernization for the Holcim Hagerstown, MD Cement Plant. The project included installation of:

- Raw mill feed bins

- Raw mill system

- Preheater

- Main baghouse,

- Alkali bypass baghouse

- Process fans

- Clinker cooler

- Modification of the existing kiln

- Transport systems for raw materials, raw meal and clinker

- Underground piping and utilities

Scope of Services

All civil/structural engineering for the project including all concrete, structural/miscellaneous steel and platework from the raw mill feed bins to the clinker cooler, main and bypass baghouses, process fans, the raw material, raw meal, clinker and cement transport systems, raw mill feed bins, process ductwork, duct and pipe supports, foundation grounding and the electrical, hydraulic and compressor rooms. The civil engineering consisted of underground piping and utilities.

An important consideration in the civil/structural work was that PENTA had to obtain approval from the local authorities to use steel manufactured and fabricated in China for the project. This required interfacing with the local authorities and providing them a detailed analysis of the Chinese steel to be used and an explanation as to how this steel would meet the IBC code.

PENTA also prepared the mechanical general arrangement drawings for the raw mill feed bins, bin building and all raw material and clinker (mechanical) transport systems and raw meal and cement (pneumatic) transport systems plus the detailed mechanical engineering for all chutes, dedusting ducts and piping systems.