Overview

PENTA can be your single-source provider for EPCM industrial plant upgrades, modifications, expansions, or construction of new greenfield facilities. Designing and building practical cement, lime, mining, industrial minerals, and minerals processing plants is our specialty. Over the last 30 years, PENTA’s innovative and practical designs have lead to projects completed on-schedule and on-budget.

Solutions

When we accepted the challenge of designing and building the Dragon Cement Plant in Thomaston, Maine, PENTA was able to provide significant savings off the single source turnkey bids this client received from OEM’s without compromising quality. We place a high priority on meeting or exceeding your success metrics for each project so you can achieve long-term success. The goal is to have each project realize an ROI in 18-36 months.

This EPCM project included a 1500 mtpd wet process conversion to a 2100/2500 mtpd dry process line. PENTA as EPCM contractor provided preliminary and final drawings, construction management, commissioning and start-up assistance, and contract close out.

New equipment designed, procured, and installed:

- Cross Bar Cooler

- Vertical Raw Mill

- Baghouse

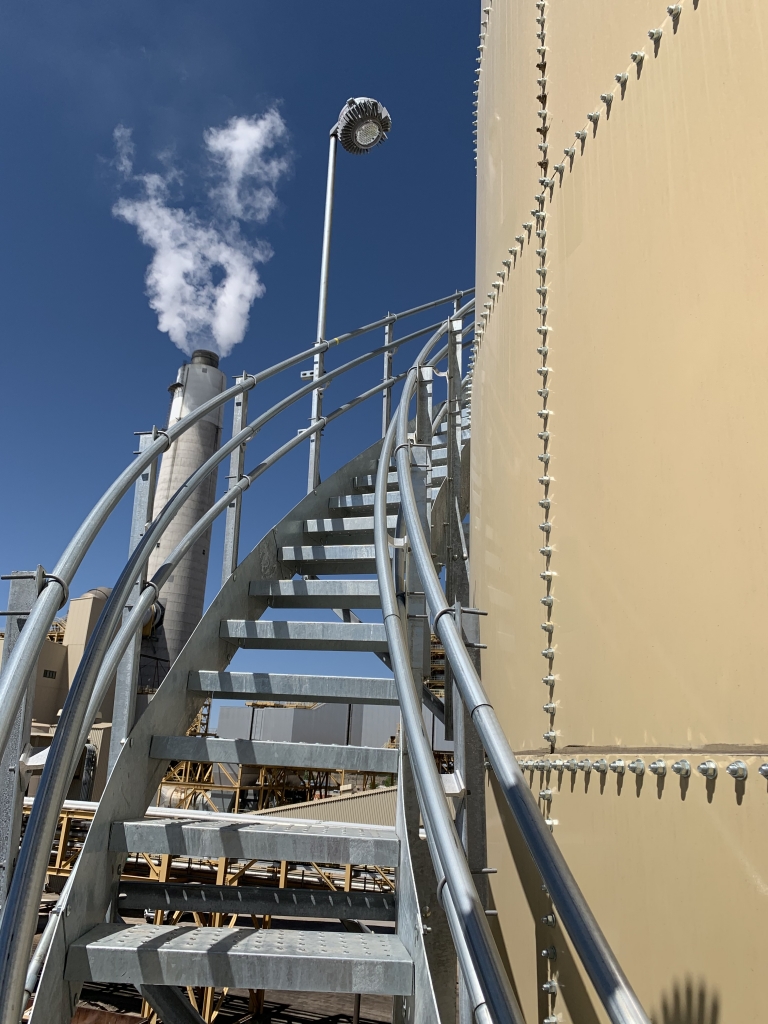

- Blending Silo

- Conversion of Raw Mill to Pre-Grinding

- All Materials Handling

- New electrical substation

“PENTA’s approach to cost effective engineering, procurement, and construction management solutions, their extensive knowledge from an operational standpoint, and their long-standing track record for providing outstanding services are some of the reasons Dragon decided to partner with PENTA when we upgraded our facility. I feel confident we will use PENTA as a resource for future projects.”

Ray DeGrass, Plant Manager

Dragon Products, Thomaston, Maine