Cement

PENTA MARKETS

Cement

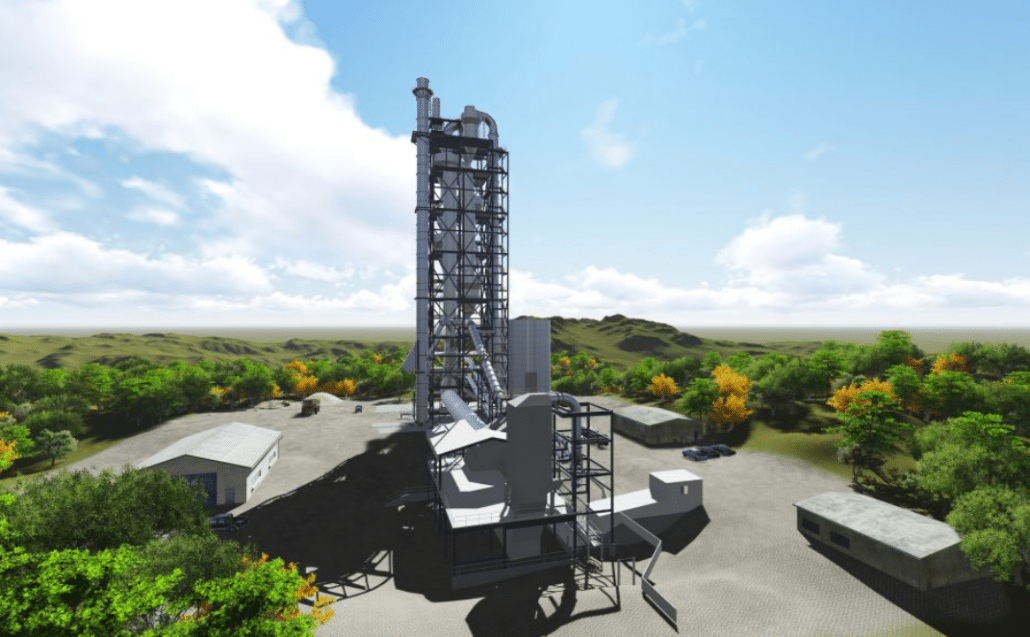

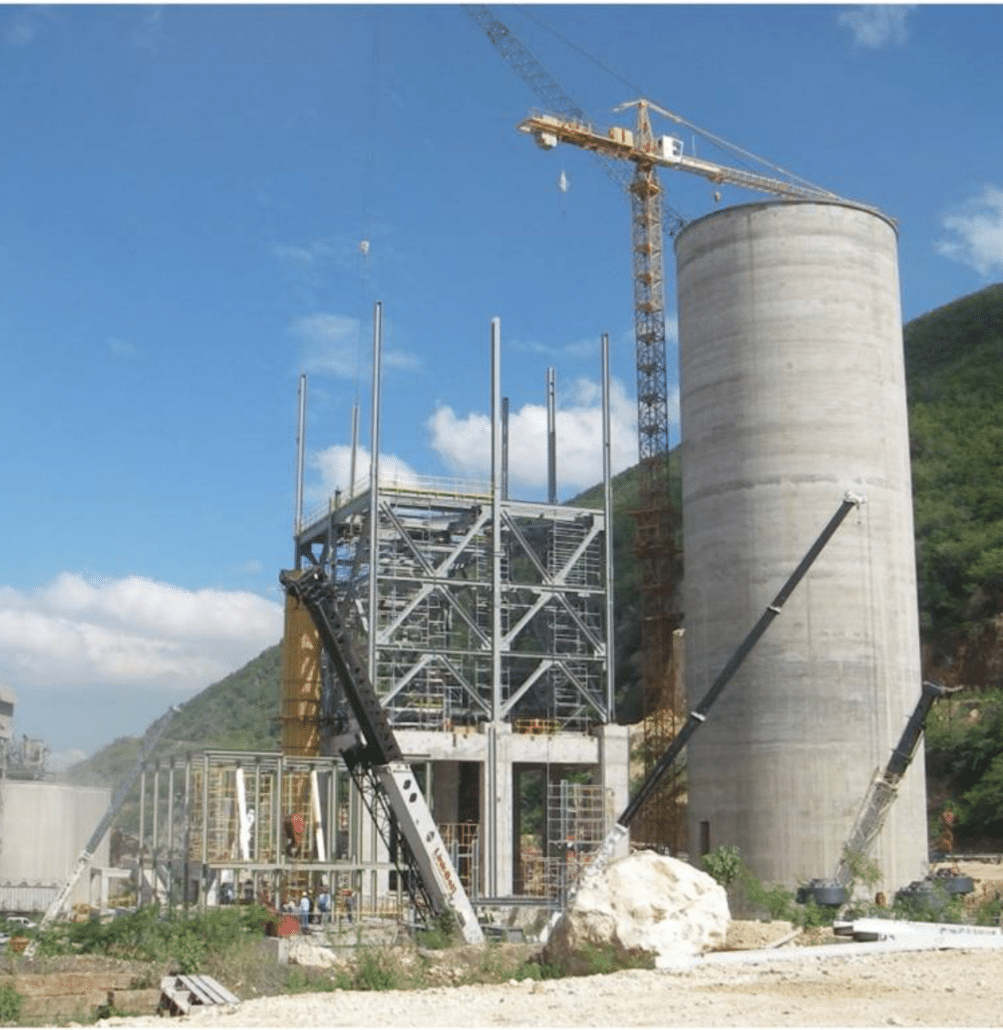

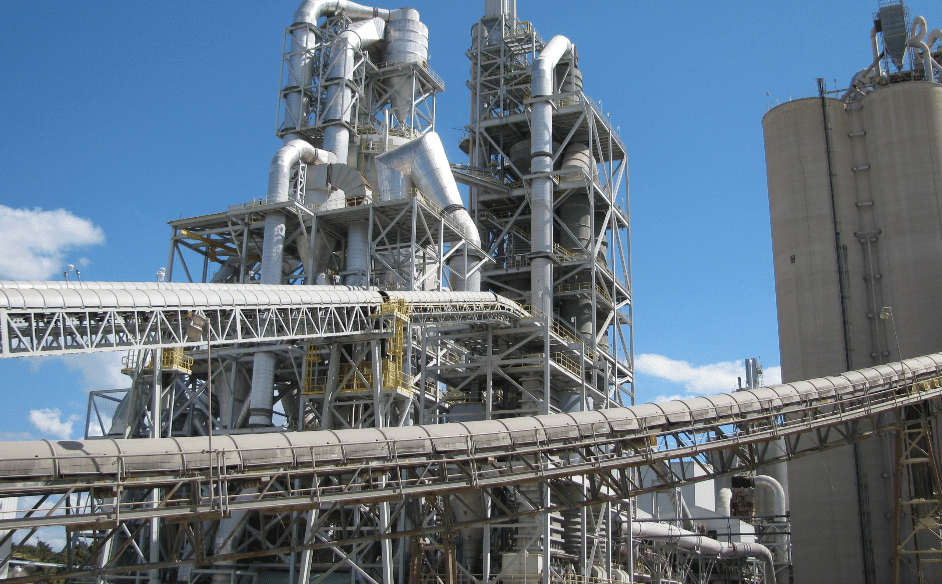

PENTA has completed improvements and upgrades to numerous cement plants globally. Our in-depth knowledge and comprehensive services combined with the extensive experience of our staff allows us to completely develop projects from conceptual design to start-up. We evaluate the needs of each specific project and provide high-technical solutions to suit every individual situation.

- Geological Evaluation, Mining & Quarrying Operations: Optimization of mineral resources including drilling, mine plans, and crushing and screening plants.

- Mineral Resource and Ore Reserve Evaluations: Our geologists, minerals characterization specialist, and mining engineers direct the core drilling, sampling, geological mapping, mine planning and reserve calculations and recommend the optimum raw mix design to extend the life of the mine.

- Engineering Design of cement plant systems. The core business of PENTA is in the engineering of heavy industrial facilities. PENTA is composed of a highly experienced multi-disciplinary team covering all phases of the engineering process for cement plant projects.

- Feasibility Studies: capital and operating cost estimates, process evaluations, and operations analysis.

EFFICIENT SOLUTIONS FOR

GLOBAL CEMENT PROJECTS

Global Expertise & Services

Extensive experience in global cement plant projects, from design to start-up.

Efficient Resource Management

Optimize mineral resources, conduct evaluations, and provide comprehensive feasibility studies.

End-to-End Support

Assist with commissioning, handle solid fuels, and engineer materials conveyance systems.

- Plant & Company Valuations: Comprehensive valuations that take into consideration business assets, historical earnings, market, mining reserves, production methods, reliability, plant personnel, management, financials and future projections.

- Commissioning and Startup: PENTA’s comprehensive commissioning plan lays out the specifics on how the project will be put into operation. In addition, PENTA assists its clients so that they can accurately plan a ramp up for production to full capacity when the project is completed.

- Solid Fuels Handling: Complete engineering of solid fuel handling facilities from process consulting to final design.

- Grinding & Milling: Design of optimum systems for drying and grinding in ball and roller mills, roller presses, classification by high-efficiency separators, cyclones, and screens.

- Pyroprocessing: Develop suitable systems of kilns, preheaters, pre-calciners, and coolers; emissions management and solid fuel firing systems; clinker handling and storage.

- Materials Handling: Belt, screw and air gravity conveyors, bucket, pan and drag conveyors; overland belt conveyors; bucket elevators; truck and rail loading and unloading systems; storage and reclaim systems.

- Bulk Storage Structures: Concrete silos & domes, steel bins, A-frame structures.

- Cement Terminals: Import terminals, truck, rail, barge, and ship.

- Instrumentation and Process Control: Design of instrumentation scheme and process control loops

READY TO OPTIMIZE YOUR CEMENT OPERATIONS?

EXPLORE ADDITIONAL

PENTA SERVICES

RECENT PROJECTS

Cement Plant Expansion Structural Engineering

PENTA supported a $500+ Million cement plant modernization project in the Midwestern United States providing structural engineering services to an international equipment supplier.

EPCM Waste-To-Fuel Facility

PENTA was engaged to develop a waste-to-fuel production facility that produces a fuel source that can be used in calcination as a substitute for fossil fuels.

Tire Derived Fuel Facility

PENTA provided the engineering for the installation of a tire derived fuel (TDF) system at a plant in TX.

READY TO

OPTIMIZE

YOUR INDUSTRIAL

OPERATIONS?

Discover how PENTA’s tailored solutions can solve your toughest challenges. Reach out for expert guidance today.